What is an O&M manual?

Operation and maintenance manuals (O&Ms) provide all the information required by end users — specifically the building asset owner or client — regarding the operation, maintenance, decommissioning and demolition of a building.

Delivered as part of the Building Manual, O&Ms are a contractual and compliance requirement for Health and Safety Executive (HSE) notifiable construction projects.

The format and contents of a Building Manual are defined in the Employer’s Information Requirements (EIRs) within the contract preliminaries, typically under clause A37.

Clause A37 covers the format, content, and structure of the Building Manual (which includes the O&M manuals) and establishes the expectations for delivering the necessary documentation.

This clause ensures that the project complies with legal and regulatory requirements, including those related to safety and the operational needs of the building once construction is completed.

It outlines the overall scope of the work and specifies the general conditions for its execution, including aspects such as subcontracting, approvals and completion dates.

The principal contractor has the responsibility to provide the Building Manual as part of a construction project, with additional information from subcontractors, designers and suppliers.

The following is standard content that should be provided in an O&M manual:

- Details of building construction e.g. finishes, cladding, doors

- Requirements for demolition, decommissioning and disposal

- Asset register of plant and equipment

- Manufacturer’s instructions for efficient and proper operation

- Commissioning and testing results

- Guarantees, warranties and certificates

- As-built drawings and specifications

“Preparing O&M documentation is an aspect of a project that takes a lot of determination and structure.”

Why are O&M manuals a challenge for contractors?

O&M manuals are a prerequisite for practical completion, yet the resource, skills and time required to gather all relevant information is often underestimated or left too late. As a result, clients become disappointed with poor quality or incomplete O&Ms at handover, which can lead to project sign-off being postponed if they deem the O&M Manuals not fit for purpose.

This can reflect badly on the contractor and may prevent valuable site staff from moving on to future projects as they rectify any problems. It also may mean that companies are not asked to tender future construction projects.

Typically, not fit-for-purpose building manuals can lead to aftercare issues during the defects liability period, leading to building managers and facilities maintenance teams being unable to maintain and manage their buildings efficiently and safely.

Top 8 reasons to outsource your O&Ms

While contractors can produce O&M manuals in-house, it often diverts valuable time and resources from the primary task of construction.

Although outsourcing O&M creation might seem like an extra expense, especially if not included in the initial budget, working with a specialist provider offers significant cost-effective benefits:

- Removes the burden from internal resources

- Eliminates stress at Practical Completion (PC)

- Provides accurate building handover checklists

- Utilises industry-proven templates and forms

- Centralises data in one manageable platform

- Ensures high-quality, consistent document delivery

- Reduces aftercare calls

- Helps establish a realistic budget for O&Ms within cost plans

Read on to discover how each of these benefits can simplify your project handover process and keep you focused on construction.

Removing the burden from internal resources

Managing the creation of Operation and Maintenance (O&M) manuals or Building Manuals internally might seem doable initially, but many contractors we’ve worked with have fed back that they quickly find the process more challenging than anticipated.

When delivering O&M documentation internally, contractors often face unexpected setbacks that can impact the project’s completion and handover.

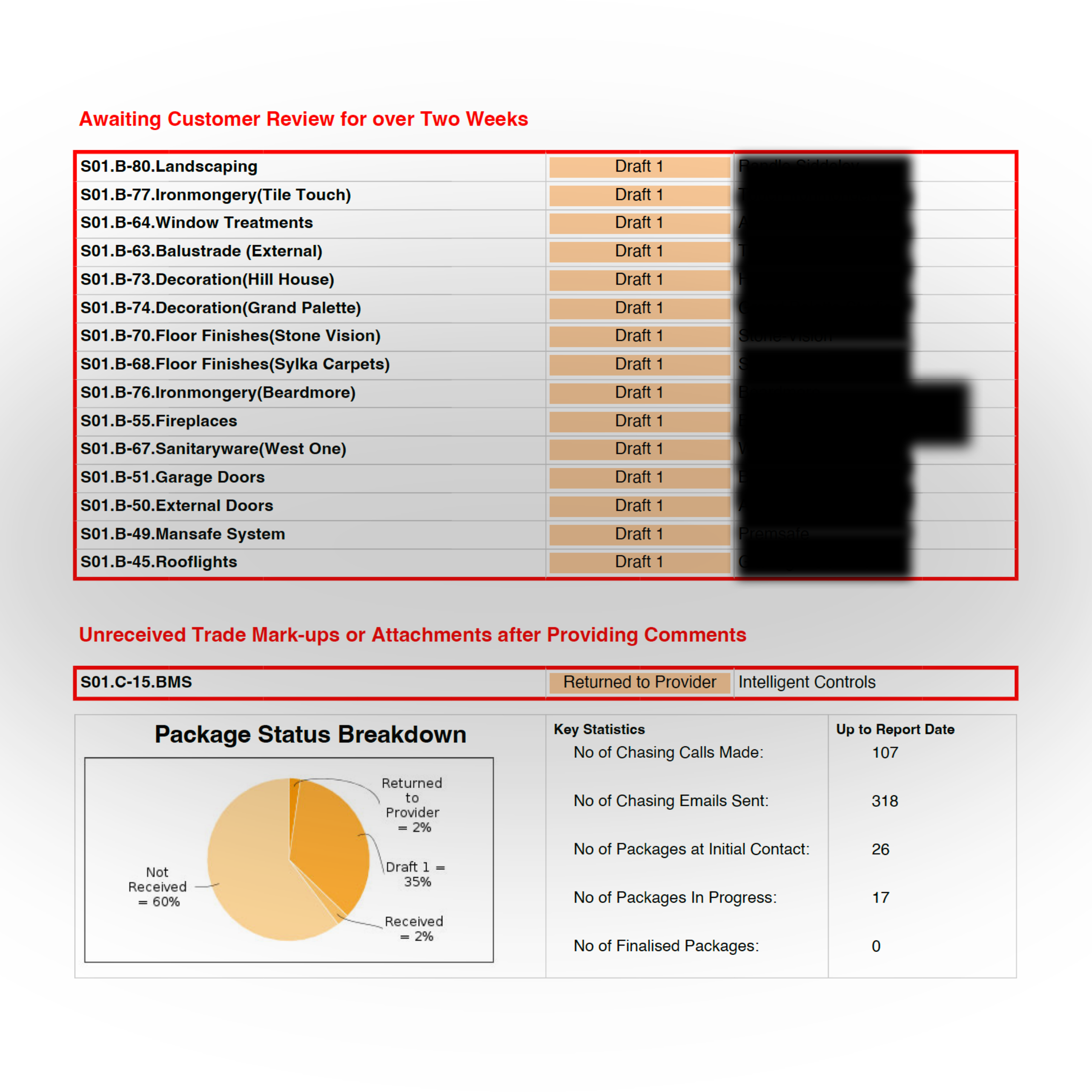

Constantly chasing trades for information

One of the biggest obstacles contractors encounter is the need to chase trades for documentation and information. The back-and-forth communication not only consumes time but often results in delays that ripple throughout the project timeline.

Outsourcing alleviates this burden, ensuring documents are accurately collected and managed without requiring extensive involvement from your team.

Effective monitoring and progress tracking

Contractors often lack visibility into O&M manual progress, especially when responsibilities are spread thin.

At smaller contractors, O&M management is often handled by junior staff, administrative workers, or apprentices who may not have the experience to stay on top of the process. This often requires managers to step in and take over, adding to their workload.

Additionally, some contractors still rely on outdated tracking tools, such as Excel, which are difficult to keep updated and don’t provide real-time insights.

Our solution offers a transparent and efficient tracking system that eliminates these challenges. By providing PDF fortnightly updates on Building Manual progress, we ensure that project managers stay informed without the need for manual checks.

This visibility into trade contributions and document status helps prevent last-minute delays, ensuring a smoother and more reliable project closeout.

Eliminating stress at Practical Completion (PC)

For contractors, managing O&M manuals can seem achievable early in the project, but as Practical Completion (PC) approaches, the pressure to close out the project, alongside the pressure to finalise documentation grows.

Waiting until the PC date draws near often brings unforeseen stress and complications that could easily be avoided by starting early and outsourcing your needs.

Avoiding the last-minute rush

A major challenge we often see is that when data collection is left until just before practical completion (PC), many trades and site workers have already left the site, making it difficult to chase down missing or corrected documentation.

If documentation isn’t managed proactively, delayed or incomplete information can disrupt your team’s ability to finalise Building Manuals, potentially causing delays, handover issues, and breaches of contractual obligations.

By partnering with us early, we engage with trades as soon as they arrive on site, ensuring documentation is collected and verified according to the schedule of works, keeping your project on track for seamless completion.

Streamlining project closeout

Zutec takes on the heavy lifting of chasing, correlating, and verifying documentation, particularly during the hectic final months leading up to PC.

This enables your team to focus on closing out the project itself, while we handle the administrative legwork of gathering O&M information. By eliminating these tasks, you reduce stress, save valuable time, and ensure a smooth handover process.

Providing accurate building handover checklists and defined EIRs through outsourced O&Ms

One of the critical components of a successful handover is a well-structured checklist that captures every detail necessary for smooth operations.

When handled internally, these checklists can often overlook specific requirements, leaving facility managers without key information they need.

By working with a specialist provider, contractors gain access to expert knowledge in developing precise, tailored handover checklists that are built around industry standards and best practices and help meet compliance and contractual obligations.

An experienced O&M provider also brings clarity to Employer’s Information Requirements (EIRs). Defined EIRs ensure all documentation aligns with the unique expectations of the client, specifying details on operational procedures, asset information, and maintenance needs.

Outsourcing ensures that each EIR is carefully addressed, minimising gaps or inconsistencies and providing a complete, usable document set at handover.

By outsourcing O&M manuals, contractors achieve a higher level of accuracy in both checklists and EIR compliance, facilitating a smoother handover and setting facility managers up for success from day one.

This clarity reduces the likelihood of post-handover issues, giving both contractors and clients confidence in the quality and completeness of the documentation.

Utilising industry-proven templates and forms

A key advantage of partnering with a provider that uses a digital platform is gaining access to industry-proven templates and forms optimised for specific project checklists and designed for easy data access.

These templates and forms are crafted to meet industry standards and refined to ensure all essential information is included, leaving no critical detail overlooked. Contractors benefit from knowing their documentation is both compliant and comprehensive.

With Zutec’s cloud-based platform, data is structured with meta-tags for easy searchability. This setup allows project managers, document controllers, and design managers to quickly locate the exact information they need, whether for approvals or final documentation reviews.

This ease of access saves time, reduces the risk of misplaced data, and enables teams to proactively resolve issues before practical completion.

It also minimises potential aftercare issues, giving the team confidence that they've got everything that’s required for each specific package and that all documents are readily verifiable.

Centralising data in one manageable platform

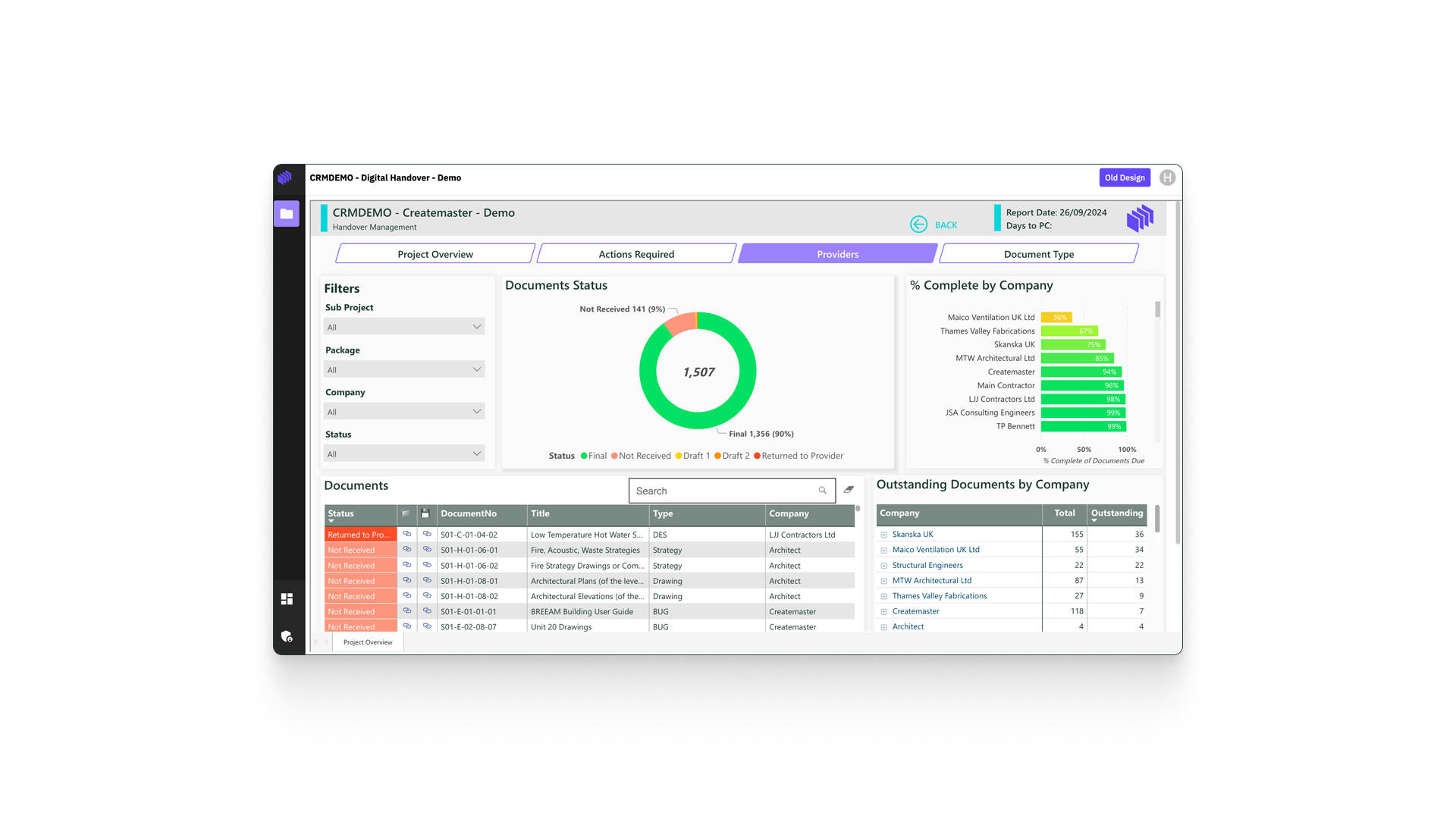

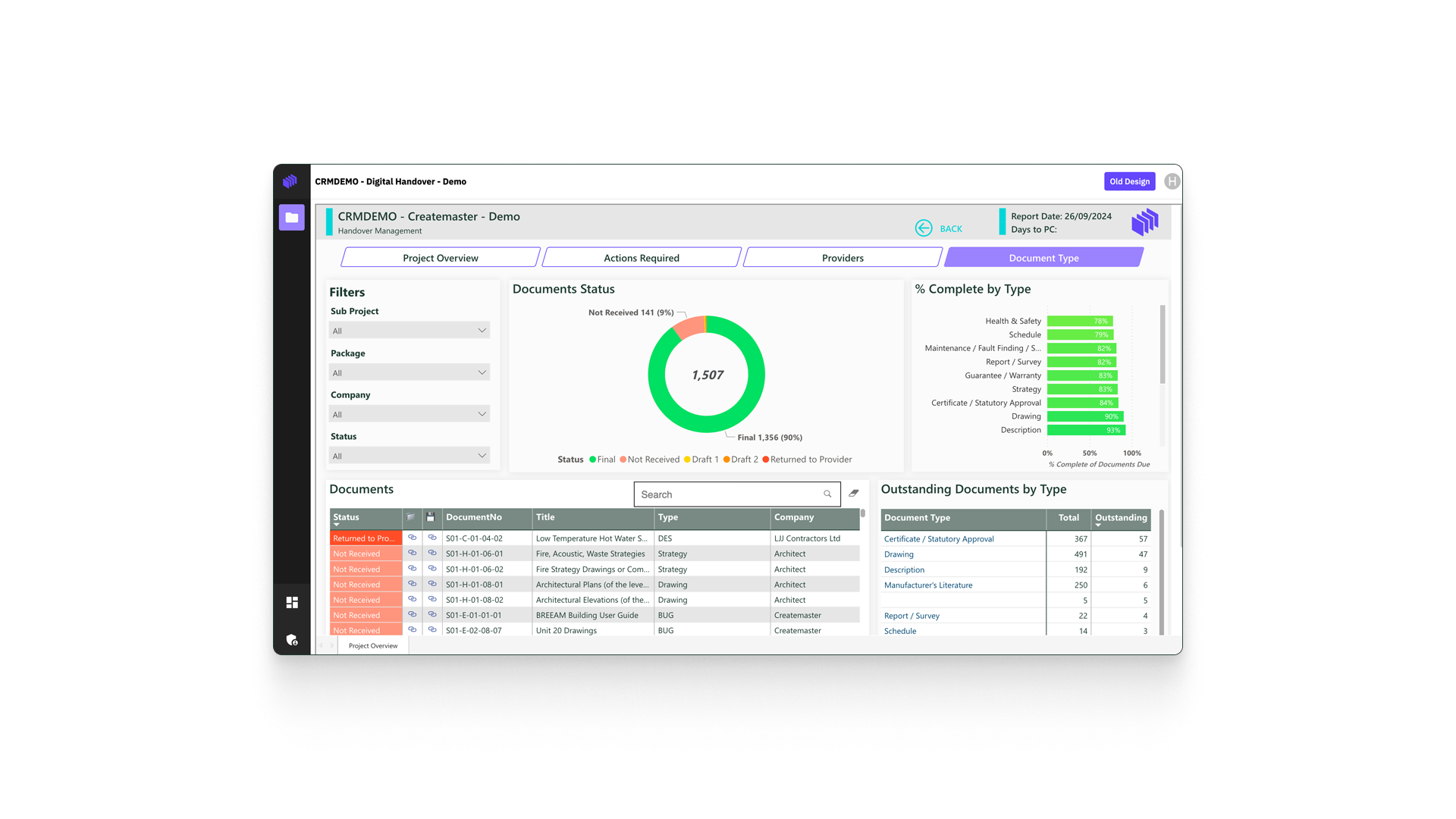

By having a single, user-friendly digital platform, all project data can be centralised, structured, and easily accessible. This streamlined approach simplifies project tracking, document management, and handover, transforming a traditionally complex and time-consuming process.

Through Zutec’s platform, contractors gain a project status overview that tracks the progress of each package in real time. The platform allows users to view expected vs. received information at a glance, which helps contractors and clients stay updated on handover progress and any outstanding requirements.

Users can view details by company type, allowing project managers and document controllers to see where each subcontractor stands and confirm whether all documentation is ready for practical completion (PC).

This centralised approach reduces the hassle of searching for documents across shared drives or third-party storage systems like Dropbox or SharePoint, and allows quick access to exactly what’s needed, such as drawings, certificates, warranties, and guarantees.

A clear overview for efficient payment processes

With Zutec’s platform, the ability to check the status of documentation completion for each trade or subcontractor also aids in smooth payment processes. By simply viewing the “Providers” tab, quantity surveyors and project managers can quickly identify which trades are complete and ready for final approval, allowing for prompt and accurate payment releases.

This insight into documentation progress helps ensure that the team chases outstanding information only where needed, avoiding delays.

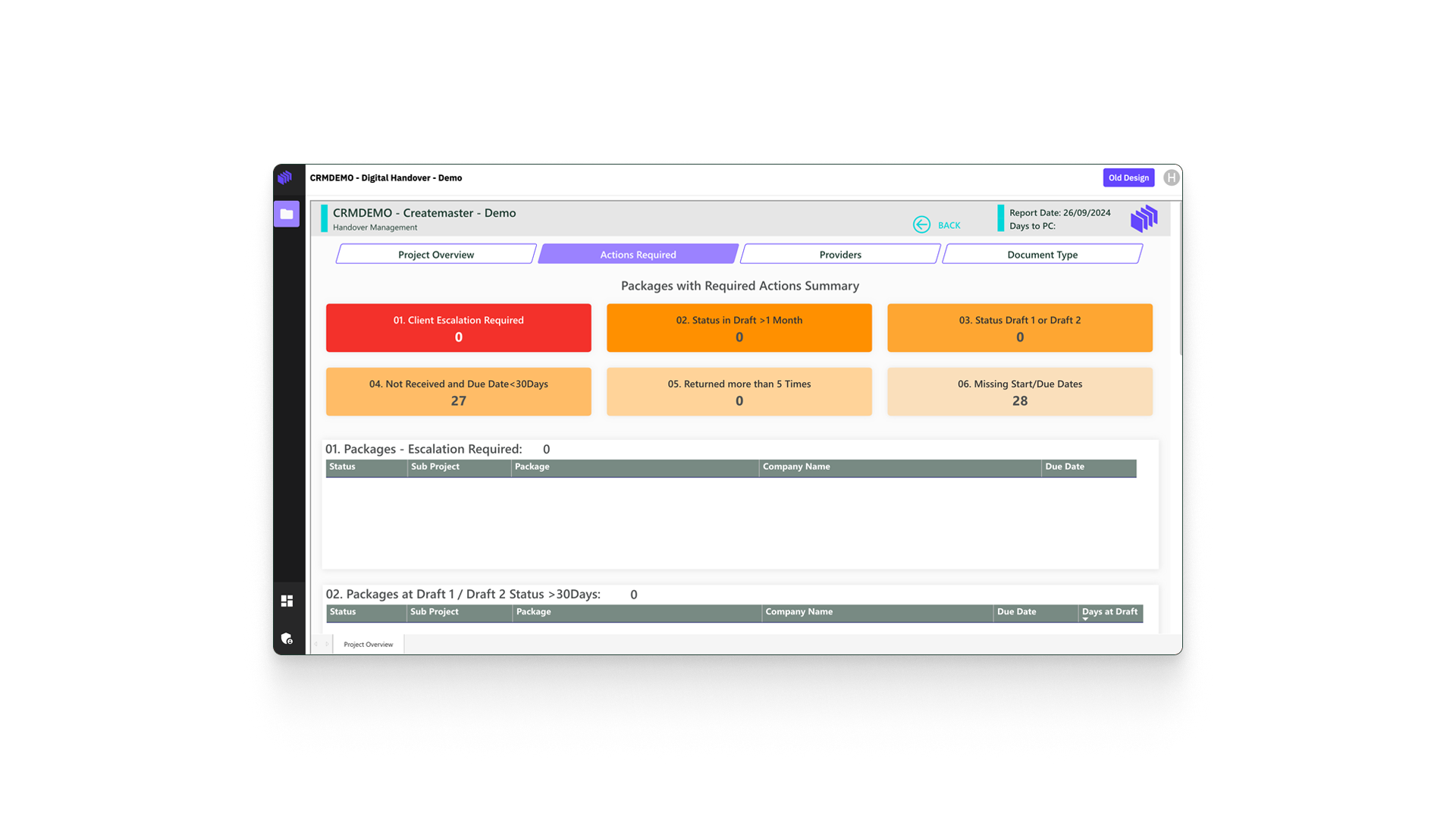

Actions and task management to keep projects on track

Zutec’s “Actions Required” tab further supports contractors by listing outstanding tasks and documents requiring review or follow-up.

This feature makes it easier for project managers, document controllers, and design managers to manage deadlines and follow up with subcontractors for any missing information, keeping the project on track.

Transparent handover for contractors and clients alike

The platform isn’t only for the contractor; it can also provide the end client with consistent updates on handover progress.

By offering clients real-time visibility into the project’s status, the platform fosters transparent communication, giving clients confidence in the project’s completion and reducing the likelihood of aftercare issues.

All information is centralised, organised, and accessible to contractors and clients alike, ensuring a smooth and reliable handover.

Ensuring high-quality, consistent document delivery

Outsourcing construction documentation is about more than just lightening the load — it’s about ensuring quality and consistency in every document.

Inaccurate or incomplete submissions can delay Practical Completion (PC) and lead to ongoing issues after handover.

Reducing incomplete and inaccurate submissions

Even with close oversight, contractors frequently find that trades submit incomplete or inaccurate documents.

This is a common pitfall when O&M is handled internally or using less experienced providers, as teams often lack the streamlined and standardised processes needed to verify and organise the sheer volume of information provided by various trades.

Our solution solves this by gathering, validating, and organising all O&M information, minimising documentation gaps that can lead to delays in Practical Completion (PC) and post-project issues.

Partnering with industry leaders

With over a decade of industry-leading experience, we’ve developed best-practice processes to manage quality O&M manuals with accuracy, reliability, and minimal effort required from your team.

By partnering with industry leaders like us, with 25 years of experience, contractors gain the advantage of an industry-recognised, standardised process that validates and organises every document from start to finish.

Our proven approach guarantees that contractors can focus on delivering successful projects on time, confident that O&M documentation is in expert hands and delivers the quality clients expect.

Reducing aftercare calls through outsourcing O&Ms

When O&M documentation is handled internally or with less robust systems like Dropbox or SharePoint, it's common for gaps and inaccuracies to slip through, leading to follow-up issues after handover.

Missing information, incorrect details, or unclear instructions can cause confusion for facility management (FM) teams, who often need to reach out for clarification — adding time and costs to both parties.

With our expert team and well-established processes, we ensure that O&M manuals are complete, accurate, and tailored to the unique needs of the project.

By validating all documentation, from equipment specifications to maintenance schedules, we create comprehensive manuals that empower FM teams to resolve most operational questions independently.

This proactive approach leads to fewer aftercare calls and minimises the need for post-completion troubleshooting, allowing contractors to focus on new projects while maintaining a strong client relationship through reliable, user-friendly documentation.

Outsourcing O&Ms ultimately gives contractors confidence that all necessary information is delivered seamlessly, reducing the administrative burden and ongoing costs associated with aftercare support.

It’s a simple yet effective way to enhance client satisfaction and streamline the transition from project completion to day-to-day operations.

Ensuring a realistic budget for O&Ms within cost plans

Outsourcing O&M manuals from the start of a project is a strategic way to ensure cost certainty. When contractors manage O&M documentation internally, use less experienced providers, or defer it until later stages, costs can become unpredictable and spiral out of control due to the last-minute coordination required to chase missing information, revise incorrect submissions, make changes or meet Practical Completion (PC) deadlines.

This reactive approach often results in added expenses that could have been avoided with a proactive O&M plan. A poorly managed building manual can also lead to more aftercare costs, which are not accounted for after project completion.

By partnering with us early on, contractors can include a realistic, fixed budget for O&M services directly within their cost plans.

With a clear approach to O&M management in place, contractors have greater control over project finances, allowing them to allocate resources more effectively and avoid last-minute expenses that could impact profitability.

Outsourcing also brings peace of mind that, as project demands and packages evolve, O&M documentation can stay on track, fully prepared for handover without compromising the project’s overall budget.

What to look for in an O&M specialist

If you’re looking to outsource your O&Ms, this should be done as early as practically possible. This enables the specialist provider to follow the construction plan and manage trades as and when they arrive on site.

Here are key questions to ask any potential provider:

- Is project handover documentation in the DNA of the company? If not, why not?

- Do they have the relevant experience, skills and resources to handle your project?

- Can they offer to host your client data post completion?

- Do they provide an asset register as standard?

- Do they have a platform for managing data?

- Is it a self-managed or fully-managed solution?

Best practice

A specialist provider should outline a fixed, managed process that underpins the way they deliver every project to ensure quality and consistency.

Their role is to provide a solution to control the flow of information in accordance with your construction programme. This is best achieved through early appointment; chasing all subcontractors, designers and suppliers for information as and when they start on site.

“Defining a set of best practice requirements ensures a standardised, quality set of deliverables at PC, which is invaluable to operational efficiency.”

On-Demand Webinar

How outsourcing O&Ms could save you time and money.

Conclusion

To summarise, O&M manuals are an integral aspect of running and maintaining a building efficiently.

Outsourcing to a dedicated single source provider should remove the burden from overstretched contractors, provide peace of mind to end clients and enable FM teams to plan for occupancy and maintenance management well in advance.