A Q&A with Phil Gillett, Head of Customer Operations at Zutec

How are you handling Part L and its requirement for photographic evidence? Are you using a Part L Photographic Evidence solution already, but struggling with mountains of photos to evidence compliance, or is it simply not up to the job?

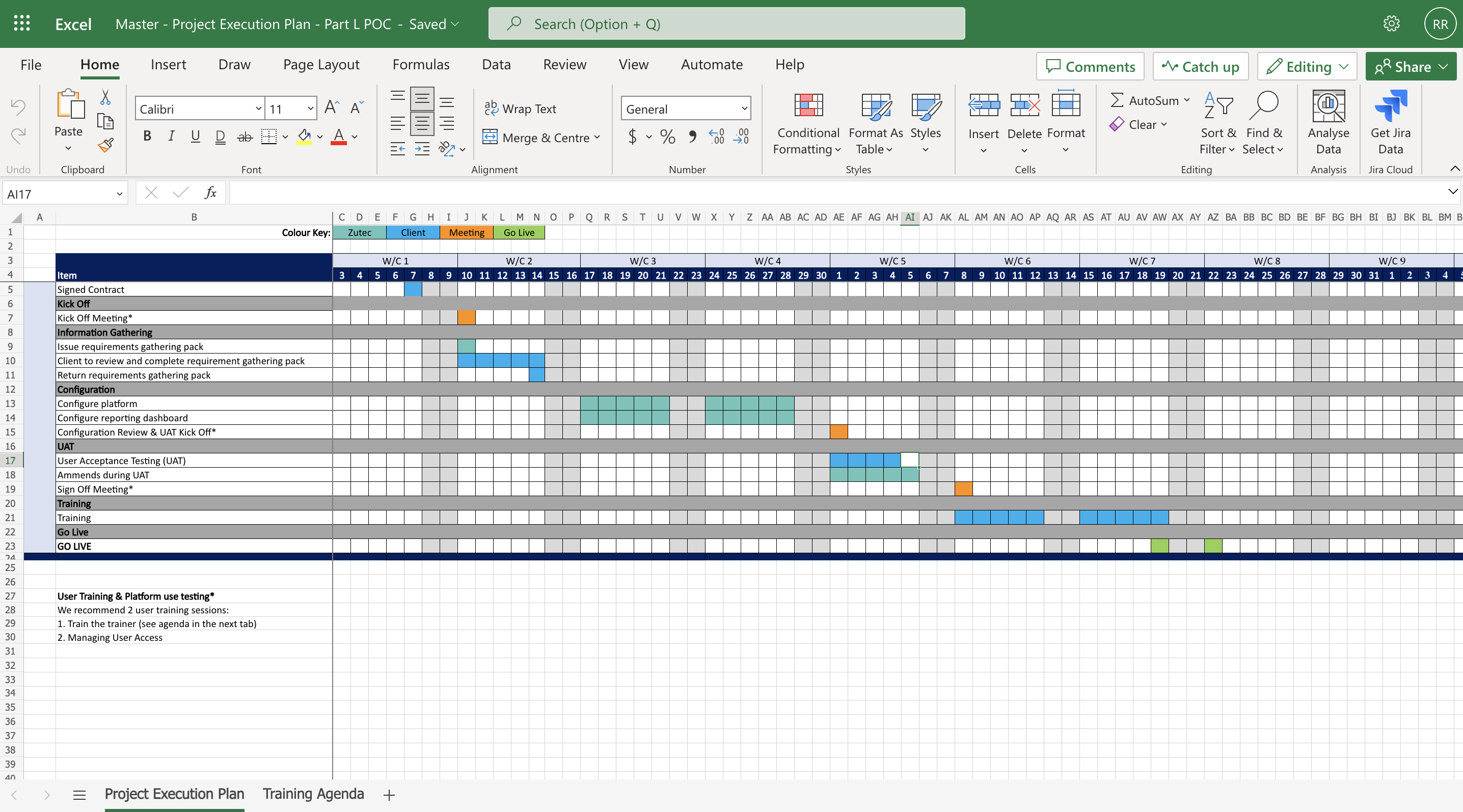

In this blog, we talk to Phil Gillet (PG), Head of Customer Operations at Zutec, and explore all the aspects of our Part L solution implementation, how long you can expect it to take, what the key milestones are and how to mitigate risk and common obstacles with a proof of concept.

Q: What is the typical timeline for Part L in implementation?

PG: We offer both an enterprise-wide solution and a proof-of-concept (PoC) version, which is typically the way to trial our solution with one project on one site. If this is the case, we can expect a PoC to run to a timeline of six weeks. Having said that, it can be completed much more quickly, across perhaps a couple of weeks if the client needs to review the solution quickly. With all these things, we find it’s heavily dependent on the client’s needs and internal timelines in most cases. From our side, it can be quite predictable as we set up all our projects with best-practice templates for Part L compliance unless the client has any additional bespoke requirements.

It gets less easy to anticipate when you look at it from an enterprise perspective, although the aim of the Zutec implementation team is to try to make this simple for our clients. Changes largely come about depending on how many projects and/or sites the client has. We will routinely create different zones within the Zutec platform for each region/business unit and each regional zone will contain all the sites in the region. For example, Taylor Wimpey has approximately 200 sites across 23 regions (project zones).

When a client goes from PoC to Enterprise they typically want to personalise the template solution and have a greater level of detail in their taxonomy. For example, they may want to refer to ‘construction types’ rather than ‘element types’ and the answer options for these may differ so they would be configured to the client’s needs. Additionally, they might want to capture an extra piece of information.

Little incremental things like this will all make configuration across the enterprise lengthier, especially if it could be across 300 sites.

In the case of St Modwen Homes, when it came to transitioning to an Enterprise Part L Solution, they decided they would also like to take on our Snagging & Defect Management solution, including an additional 10 extra checklists on top of the Part L solution. So, therefore, it's a completely custom project plan. As Zutec provides a full quality management suit of solutions, Part L may be the first solution a housebuilder implements to meet deadlines around regulatory compliance, before rolling out other solutions for snagging, Health & Safety or Quality Assurance.

If a client wants to progress to an enterprise-level solution just by taking the PoC template, we could be looking at six to eight weeks to roll out if it's exactly the same, which is extremely quick for a solution like this. And if an enterprise client only has seven sites, as an example, that could be more like four to six weeks. So, implementation all depends on the number of sites as well.

“As a leading UK Housebuilder, building high-quality homes is at the heart of our business. We have now worked with Zutec for over two years, deploying their solution across more than 1,000 users and 200 sites. The Zutec platform has enabled us to transition to the 2021 Part L building regulations with a clear audit trail of photo evidence for internal reporting and a workflow to resolve issues quickly. Using Zutec supports our goals to deliver much-needed homes and drive operational excellence across our business.”

Q: What are the key milestones for a Part L project?

PG: If we take six weeks as the agreed timeline, this will be broken down in sections across a six-week plan: Kick-off, information gathering, configuration, User Acceptance Testing (UAT), training and go live. When a project is using our best practice templates for Part L compliance, the information gathering, and configuration sections can be quite straightforward.

Information required will include data such as a list of the site management team, names of the quality manager who will be reviewing the records, as well as details of the SAP Assessors, and includes project and plot details for drop-down menus, workflow processes and notifications. If the client is able to review and complete the requirement gathering pack and return it back to us promptly, we can get the client moved onto UAT much quicker.

Once the client is set up on the platform, they can then play around with the solution and test it. This is exactly what a PoC can be used for. At this point, they might come back with feedback on how they’d like to tweak certain things within the configuration if it doesn’t quite sit right for their internal processes or needs.

We’ll then be able to make updates to the platform in real time as they continue to use it until everyone is satisfied with the structure. Once clearly defined and set up, we can then go into training ahead of go live.

Part L Photographic Evidence made simple

Capture, store, share, and manage Part L photographic evidence with a dedicated solution to speed up BREL report submissions.

Q: What does a kick-off call normally consist of to get a Part L project up and running?

PG: The kick-off meeting runs to an agenda that aligns with the project milestones as mentioned above. We’ll start the meeting understanding who the team will be on the client side. Then we’ll talk through the steps explained above, as well as the differences between the mobile app which the site managers will use to capture site data in the field, and the web application which everyone else will use, and where they will do their reporting.

At this point, we’ll explain what construction photographic evidence is according to the Buildings Regulations England Part L (BREL) report and why photographic evidence should be digital to prove that building work complies with Part L standards.

Each customer may approach the photographic inspection workflow differently. Some may have Quality Managers who must review, approve or reject photographic evidence ahead of being sent to the SAP Assessor. Others may send directly to the SAP Assessor for their feedback first. Everyone is approaching the new legislation slightly differently.

Q: Are there any common obstacles in implementing Part L?

PG: Typically, you’d expect to come across some opposition to adopting new technologies within the client organisation as we are digitising a still largely non-digital industry. The biggest problem we’ve had in the past is inconsistent engagement across client teams. For example, one client who wanted to roll out a solution across two sites found that the site more heavily connected to their head office experienced far less resistance than the site that worked more in silo.

In addition, we have to bear in mind that these teams are on-site and using an app isn’t their top priority when they have a project to manage and deliver. At the same time, it’s important to be clear on expectations. The client is buying a platform and the solution will only work if we receive the correct information for implementation in a timely manner and an effective training programme is undertaken. With new legislation putting firm deadlines in place for clients to demonstrate compliance, we’re finding these blockers less of an issue.

To combat any residual onboarding issues, we make sure we have a central team we liaise with to create ‘super users’ who in turn train the end users. These are people who can lead by example and encourage their colleagues to get the most out of the platform. We find having focused training for super users is integral to the success of an implementation. In addition, we have an account-based marketing team that supports the customer with user engagement and adoption.

Q: Do clients have to adopt project management software during implementation?

PG: We like to make implementation as straightforward as possible and focus on the solution tech rather than adding another layer of confusion by using implementation project management tools. In many industries, this type of software can be a great way to improve project planning and execution. But when clients may already be reluctant to use technology in their day-to-day in the first place, it’s far better to focus on learning how to use the solution they require to complete compliant projects efficiently and effectively, rather than having to navigate new implementation project management software at the same time.

In some instances, we could be running a training session on Zoom while the client is on-site, and they are called out to look at a plot. When time is limited, the road to implementation needs to be as simple as possible. We find our clients prefer to work over email, phone and video calls.

If you’d like to understand more, have any questions or would like to try our solution with our Part L proof of concept before making a longer-term investment, book a demo with one of our experts today. Or watch our video to see how a centralised platform, accessible on both desktop and mobile devices, can collect evidence on-site and manage workflows, tracking and approvals.

Whatever your situation we've got an out-of-the-box tool to simplify capturing, storing, sharing, reviewing and submitting photographic evidence for EPC and BREL reports.