Construction handover is one of the most critical stages in the build lifecycle – the point where responsibility, risk and information formally pass from contractor to client. Done well, it supports safer operation, smoother Facilities Management (FM) and a better client experience; done badly, it creates disputes, delays and aftercare headaches.

This comprehensive guide for UK contractors combines best practices and insights drawn from Zutec’s experience delivering over 5,000 digital handovers. Use it as a hub for your team and as a starting point for standardising construction handover templates, O&M manuals and dashboards across projects.

The 10-step checklist for seamless construction project handover

What is construction handover?

Construction handover is the formal transition of a completed asset from the main contractor to the client or operator, usually around practical completion and into the defects period. It covers not just the building fabric and systems, but also the information needed to operate, maintain and manage that building safely and efficiently.

On a typical UK project, handover includes final inspections and snagging closeout, commissioning and client training, formal signoff and delivery of a complete construction handover pack.

That pack, including all the operations and maintenance (O&M) manuals, should follow a clear handover template and be structured so that facilities managers can quickly find the information they need when they need it, not just tick contractual boxes.

What should a construction handover include?

A robust construction handover pack gives the client everything required to safely occupy, operate and maintain the building from day one. While details vary by contract and asset type, most packs will include the following core documents:

- O&M Manuals: How to Operate & Maintain the Building

- Detailed guides covering how to safely operate, maintain, and service installed systems, materials, and components. Includes manufacturer literature, maintenance schedules, contact details, and warranty information.

- Health & Safety (H&S) Files: Essential Safety Information

- A legal requirement under Construction (Design and Management) Regulations, the H&S File contains vital information for the safe future use, maintenance, and alteration of the building. Includes significant residual risks, key design assumptions, and structural details.

- Asset Registers: A Record of What’s Installed

- Structured list of all maintainable assets within the building, including serial numbers, locations, models, and maintenance data. Used to support facilities management.

- Building User Guides (BREEAM): Simple Instructions for Occupants

- For facilities managers, occupants, and maintenance teams of commercial or multi-occupancy buildings. Includes building-wide operational details, sustainability features, and environmental performance information to help meet BREEAM credits.

- Log Books: Operational Performance Records

- These track building performance against design targets over time, particularly for sustainability and energy usage. Often required under Part L or BREEAM, especially in commercial buildings.

- Fire & Emergency File (FEF): Critical Life Safety Data

- Contains all fire-related safety information, including fire strategy, compartmentation drawings, and equipment specs. Mandatory for residential buildings post-Grenfell, supporting compliance with the Building Safety Act.

- Home User Guides: Focused on individual residential properties.

- A simple, user-friendly document for new occupants, explaining how to operate and maintain the home’s systems, use appliances safely, and access key contacts or emergency info. It ensures safe, efficient living from day one.

Standardising these elements in a repeatable construction handover template means every project starts from the same strong foundation. Dedicated digital handover tools like Zutec then help you capture, validate and package this information into polished digital O&M manuals rather than ad hoc file bundles.

How does the construction handover process work?

At a high level, the construction handover process runs from early planning to post-handover support. This allows for:

- Planning handover early, defining requirements, templates and responsibilities as part of preconstruction.

- Embedding those requirements into procurement so the supply chain knows exactly what to deliver, when and in what format.

- Collecting, reviewing and approving documentation progressively during construction, not just at the end.

- Structuring the handover outputs so they work both for construction phasing and for long-term asset management.

- Using digital dashboards and workflows to maintain visibility, track progress and manage approvals.

- Delivering a complete, client-ready construction handover pack to support a smooth transition into the defects period at practical completion.

The remainder of this guide takes that process and breaks it into ten practical tips you can apply on every UK project.

Why does construction handover go wrong?

Despite best intentions, many construction handovers still feel chaotic. Common root causes include:

- Late planning, with handover treated as an administrative task rather than a defined project phase.

- Unclear handover requirements for subcontractors, leading to incomplete or inconsistent O&M manuals.

- Lack of standardised templates and checklists, so every package looks different.

- Overreliance on Excel trackers and email chains to manage hundreds of outstanding items.

- Assuming a Common Data Environment (CDE) can simply be exported at the end to create a usable handover pack.

By addressing these issues systematically – starting early, defining clear templates and using digital handover tools – contractors can turn project closeout into a repeatable strength instead of a recurring pain point.

Top 10 tips for seamless construction handover

The following ten tips translate best practice into day-to-day actions your teams can take. Each tip links out to a deeper Zutec article for more detail.

1. Start early on handover planning

The first rule of a smooth construction handover process is simple: start early and keep going. Handover is a process that should run in parallel with design and construction, not a single milestone in the last month on site.

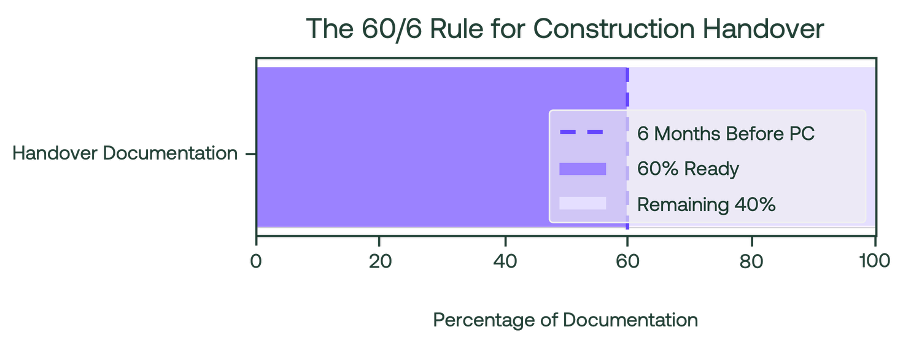

Put clear handover activities into the programme and begin collecting documentation well before package completion. Aim to have around 60% of your handover information drafted six months before PC, then use scheduled interim reviews to spot gaps and fix issues while there is still time. Gather O&M manuals, product data and certificates incrementally rather than in one big push and use digital tools and specialist teams to send reminders, manage deadlines and keep information flowing steadily instead of in spikes.

Read how to put ‘start early’ into practice in our guide on why construction project handover is a process, not an event.

2. Set your construction supply chain up for success

Your supply chain will only deliver high-quality handover information if it is set up to do so from day one. Vague requests for “O&M manuals at PC” leave too much room for interpretation and almost always lead to rework.

Include detailed handover expectations in procurement. Define exactly what each subcontractor must deliver, in what format, and by which date. Then share trade-specific templates and construction handover checklists to make those expectations tangible. Monitor submissions during the job for completeness and consistency rather than waiting until the end and use digital progress tracking and dashboards to make each trade’s status visible.

This builds accountability, simplifies chasing and helps ensure everyone understands that documentation is part of the package, not an optional extra. Read more in our blog, ‘How to Set Your Construction Supply Chain Up for Success’, or download our Playbook to learn why most supply chains struggle at Handover (And what you can do differently).

3. Use a standard construction handover template

Without standardisation, every package looks different, and the final O&M set is hard to navigate. One trade might supply polished, structured handover documentation, another might upload a handful of unlabelled PDFs. The client experiences this as friction.

Create a standard construction handover template that defines the overall structure for the project – the sections, folder hierarchy, required documents and naming conventions. Then build checklists for each trade, outlining exactly which documents are required for each package, from product data sheets and commissioning certificates through to warranties and maintenance schedules.

Every submission should then be validated against the requirements as they arrive. This combination of templates plus real-time validation turns a messy pile of files into a consistent, client-ready digital O&M manual set.

Read the playbook for practical steps to ensure every trade delivers exactly what's needed, in the right format.

4. Align your handover with site geography

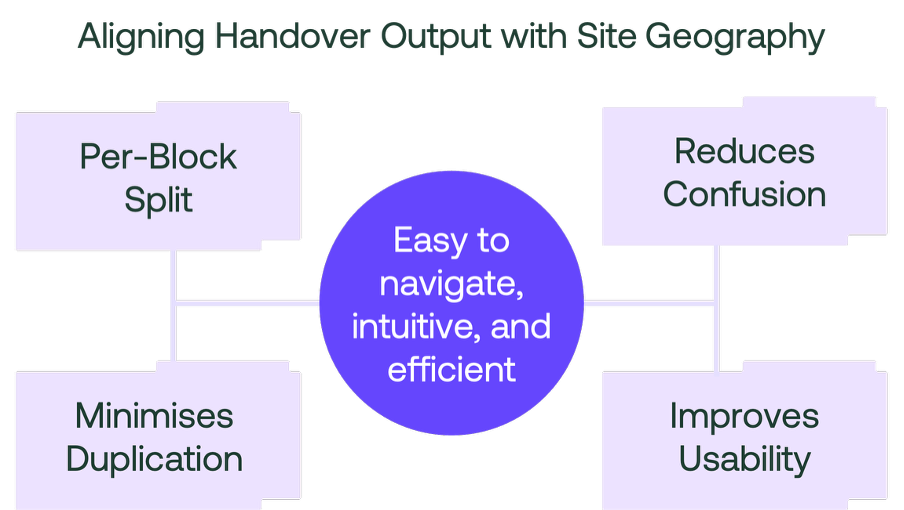

The way you build a project and the way the client operates it are rarely identical. Site teams think in terms of packages and contracts; facilities managers think in terms of blocks, floors and individual units.

To bridge that gap, agree early how your handover outputs will reflect both construction phasing and long-term asset management. Structure your handover to align construction handover with site geography so information can be accessed by block, phase, tenure or asset type, not just by trade. Apply tagging so FM teams can easily locate the required document, rather than searching through contractor-centric bundles.

Download our playbook to learn why geographic alignment makes your handover pack far more usable for facilities teams.

5. Make one person accountable for handover

When everyone owns handover, no one truly owns it. A single accountable lead keeps the construction handover process on track. Assign one person – often a dedicated handover or package manager – with clear, sole responsibility for driving the handover process. Make it explicit that this role covers coordination with trades, internal teams and the client, not just admin.

Support them with fortnightly reports and dashboards that show progress by package and document type, so they can keep on top of submissions, reviews and approvals, improving transparency and addressing any issues ahead of completion. This helps identify issues quickly and protects the business if questions arise later.

6. Define a clear approval process

Even when documents are submitted on time, they can still get stuck in review. If it is not clear who approves what, or how long they have to do it, the construction handover process can become a stressful rush at project closeout.

Create a simple approval matrix that sets out, for each document or package, who reviews it, who signs it off, and what happens if deadlines are missed. A clear digital approval process keeps work on track and creates a reliable record of approvals, so the client ends up with a high-quality, verified digital record that supports long-term asset management and compliance.

7. Agree the final handover output early

Too many projects are still governed by legacy clauses that assume paper O&M manuals and static tables of contents. If you do not address these early, you may end up complying on paper but undermining the digital value of the information you provide.

Engage the client and FM team at the outset to agree what the final handover should look like beyond paper. Discuss how the information will be structured and how it should align with their existing systems or golden thread strategy. Make sure your approach satisfies contractual and regulatory requirements, but also use a digital handover specialist like Zutec in a way that supports more modern, usable outputs. Demonstrating sample digital O&M manuals or dashboards early on sets expectations and avoids having to retrofit formats after you have moved your project team onto the next job.

8. Provide early visibility with live dashboards

There is often a temptation to keep handover conversations quiet until documentation is “almost there”, in the hope of avoiding pressure from the client. In reality, that approach can result in unpleasant surprises and reactive aftercare once the building is occupied.

Instead, normalise early visibility. Use dashboards to show live handover status throughout construction – by package, by block and by document type – and give both internal stakeholders and the client-controlled access to that view. Share regular updates that flag issues early, along with the actions being taken to resolve them. This proactive openness builds trust, encourages earlier engagement from everyone involved and significantly reduces the risk of a last-minute scramble at PC or a long tail of avoidable aftercare issues.

Read the ‘Project manager’s guide to smooth project closeout’ to master the digital construction handover process.

Discover why confidence at handover starts with visibility in our flyer for Project Managers.

9. Don’t rely on CDEs alone for handover

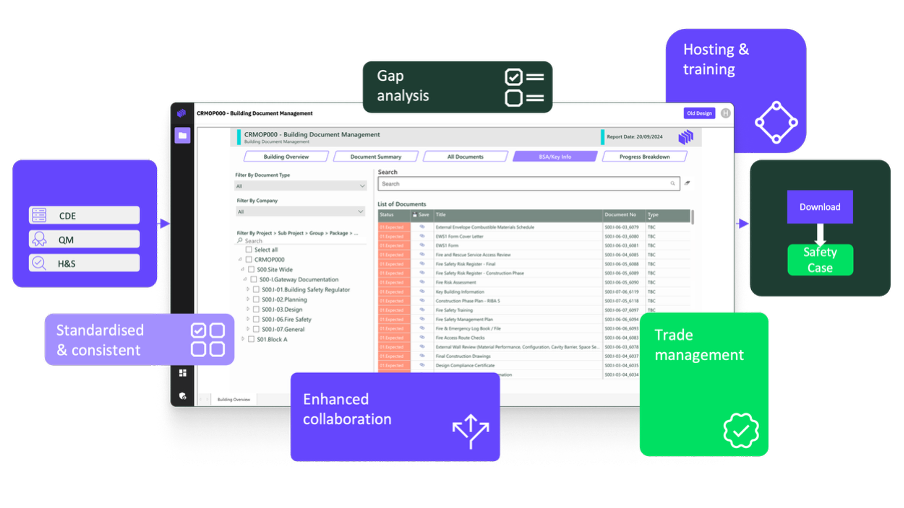

A CDE is essential for managing drawings and documents during construction, but it is not designed for what happens after project completion. This is why CDE platforms fall short at handover. Simply exporting folders from your CDE and handing them over can leave the client overwhelmed and unsure where to start.

Complement your CDE with specialist digital handover tools and teams that focus on the structure and usability of the final output. Organise information by asset, location and package so it can be filtered and searched intuitively, and use those tools to assemble polished, digital O&M manuals rather than raw, unusable data dumps.

10. Replace Excel handover trackers with dashboards

Excel has long been the default way to track O&M and handover tasks, but on modern, complex projects, Excel is no longer fit for purpose. Manual updates, multiple versions and broken formulas all chip away at confidence in the data just when you need clarity most.

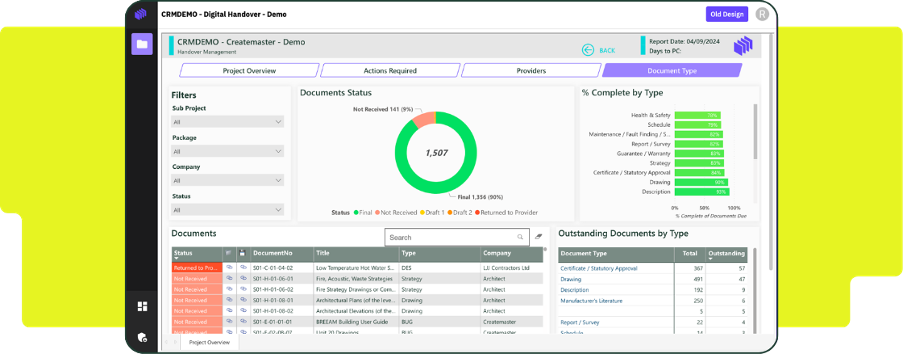

Replacing those spreadsheets with live dashboards transforms how you manage handover. When your tracker is powered directly from your handover platform, it updates itself as documents are submitted, reviewed and approved. Everyone sees the same “single source of truth”, without someone spending hours each week reconciling files. That saves time, sharpens decision-making and helps you present handover status to clients in a way that looks professional and is easy to understand.

Making this your standard construction handover process

Taken together, these ten tips form a practical blueprint for a repeatable, digital construction handover process. By starting early, guiding your supply chain with clear templates and checklists, aligning outputs with how the building will be managed and using dashboards instead of spreadsheets, you can turn project closeout from a risk point into a genuine point of difference.

Digital tools and dashboards for construction handover

Modern digital handover solutions like Zutec take much of the manual effort and risk out of project closeout.

Instead of juggling documents, spreadsheets and email threads, you can:

- Capture, create and validate digital O&M manuals, fire and safety files and as-built information in one place.

- Use structured data and tags to support golden thread requirements and asset management.

- Drive seamless submissions, reviews and approvals, with managed reminders and escalations.

- Give internal and client stakeholders access to live dashboards that tell a clear story of progress.

Further reading on construction handover

This further reading serves as a central hub for construction handover best practices.

Explore deeper articles and further insights into the topics covered in this blog below.

Construction handover FAQs (2025)

Q: What is the difference between construction handover and practical completion?

A: Practical completion is the point at which the works are substantially complete, and the client can take possession; construction handover is the broader process of transferring the building and all necessary information, often beginning at PC and continuing into the defects period.

Q: How long does construction handover take?

A: The practical handover phase around PC may last a few weeks, but the most effective teams start handover planning months earlier and continue supporting the client through the full defects period.

Q: Who is responsible for construction handover on a UK project?

A: The main contractor usually leads the process, often through a project manager or dedicated handover manager, with support from subcontractors, digital handover providers and the client’s FM team.

Q: What is the best way to manage construction handover documentation?

A: Use a structured construction handover template in a digital platform that supports progressive capture, gap analysis, approvals and dashboards, rather than ad hoc folders and spreadsheets.